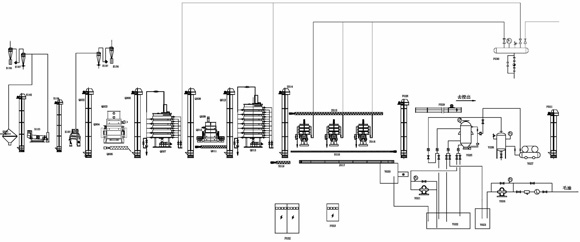

Actually, the cotton seed oil mill machinery process includes several procedures. First of all, the cotton seed will be sent into shaker room for cleaning, the clean cotton is sent to the grinding room to remove the linter from the cotton seed. Next cotton seeds will be sent through hullers, where the tough seed hull is removed. Seeds acquire the shattered part of this is the kernel containing more oil such as urgently needs to be part of the oil recovery. The cake is included in the oil pressing plant through the solvent extraction. So get oil washing and refined in order to get the edible cottonseed oil. All of these process seamless integration for a smooth operation.

Fried the seeds evenly, fire cannot be too high, lest the shell easily burned. Stir the cottonseed after grilled with the rod, make the hot steam cold and clean them by the sieve. Use artificial screen or fixed screen to eliminate impurities. Add water along the grinding roller ring groove, a turn seed, make the billet draft evenly, grinding consistent, run for about 20 minutes until the thin slab does not block. When put the powder into steam barrel, flat it to make steamed barrel breathable even, the temperature and moisture should be consistent.

Steam barrel bottom should be round as back form, in order to heat evenly, steam pan water level consistent, and steamed barrel bottom and the water surface distance from the 16 centimeters of above advisable, burning to divide evenly. Operator should master scattered packet cake, fast to packaging flat tight, concentrated and fast. The bread after squeezing is about 2 cm thick or so, should try to shorten the time, prevent heat loss. At the beginning when the bread is on, adjust the circle and the distance of the circle, lest bread play unevenly. If the oil line breaks down then squeeze for 2 hours before the loose. Oil squeezing out contains many impurities. Should cool it, and lay it up for a long time before filter, in case the color and luster is deepening, increase refining losses.

没有评论:

发表评论