Numerous variants of oil mills exist; some could have multiple crushing stages while some have only single stage crashing stage. Among the most important considerations when selecting an oil mill plant for both big scale and small scale generation of vegetable oils will be the efficiency, safety and power consumption. It is suggested that prior to you decide to purchase an oil mill plant, a thorough understanding of how every oil milling element, you are impressed in performs. This information can be obtained by requesting the specification of every plant from their respective resellers or manufacturers. More information may also be obtained from personnel inside other established oil milling plants.

Presently, you will find numerous ways of extracting these oils, these techniques can be grouped into two categories namely; chemical extraction and mechanical extraction. Basically in big scale production, probably the most appropriate technique of extraction the oil is via crushing or pressing. Practically all edible vegetable oils are extracted this way regardless of becoming somewhat wasteful since a considerable portion of oil will remain in the vegetable seed remnants. Nevertheless in some cases, both crashing and chemical extraction is employed hence minimizing oil wastage.

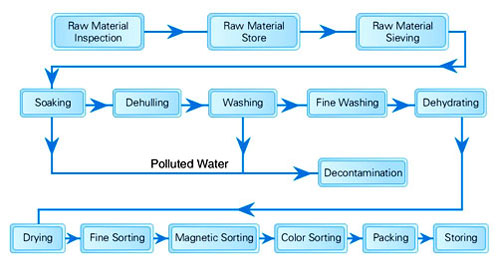

The vegetables need to be refined for creating the extraction procedure more efficient and also to rid supplies that are not required prior to they are able to be pressed to extract oil. The process is generally carried out by utilizing skin and husk removers, steam cookers or chemical substances. This process in its entirety is referred to as cooking.

Industrial cottonseed oil extraction process might involve 1 or each of the following modes of extraction; cold pressing and hot pressing. After the pre extraction stage which removes any undesirable vegetative matter this kind of as skin, shell, husks and so on next comes cold pressing. Cold pressing normally takes location at managed temperatures which range in between 60 degrees and 70 degrees centigrade. The measure is carried out to prevent protein denaturalization and you might not understand that in the oil bearing in mind that the majority of the nutrients in unprocessed oil are extremely sensitive to temperature and may be broken by higher temperatures, the temperature is suitable to protect nutrition. This will happen after cold pressing in plants using each extraction techniques, else, the hot pressing follows at this stage, the temperature normally is maintained well above 100 degrees centigrade and this technique has a a lot greater oil output in comparison with cold pressing.

Namely plate filer press and frame filter press are two specialized kind of press which comes as filter procedure. The two techniques aimed exact same but function differently, as you can know from the title, this stage will purify the oil by separating the pure oil from foreign substance.

The oil that flows out of the filter press is then packed into containers as vegetable oils, hydrogenated to type vegetable fats, or additional processed in other locations from the oil mill plant to suit other uses.